| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : ACCUVON

Model Number : AC 50

Certification : API , IOS , CE, 3A , FDA

Place of Origin : Guangdong , China

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, D/P, T/T, Western Union, MoneyGram

Supply Ability : 1000 Pieces per Month

Delivery Time : 8 - 12 work days

Packaging Details : Export wooden box packaging

Flow : 20 m³/ h

Temperature : 80℃

Rotation : Clockwise/Counterclockwise

Rotor Material : SS316

Rotor type : tri-lobe screw SS316 Rotor

Scope Of Application : High Viscosity/Corrosive Chemistry

Seal Type : Mechanical seal SIC/FKM

Application : Chemical Industries

Stainless Steel Rotary Pumps For High Viscosity/Corrosive Chemistry

Rotary lobe pumps

Accuvon is a specialist in rotary lobe pumps. We offer solids-resistant rotary lobe pumps with flow rates of 1–24,000 l/min and a large selection of equipment and additional parts. The pumps can be used as mobile, stationary or submerged versions.

Working principle:

Twin-Rotary pumps are multi-functional and bi-directional positive displacement pumps, produced with fine technology. The manufacturing engineering and precision of the pumps approach the advanced level of the world. Rotary pumps use synchronic rotors, driven by a pair of synchronic gears in the gear box. Transmitted by the main shaft and the sub-shaft. The rotors move synchronically in counter-clockwise directions, which, consequently, varies the pump capacity and builds up high vacuum capacity and emission pressure. It is particularly suitable to pump sanitary medium, high-corrosive and high-viscous medium.

Specifications:

| Description | Stainless steel lobe pumps |

| Rotor | SS316 rotor |

| Seal | Double mechanical seal |

| Axial and radial casing protection | High-strength steel , resistant to wear |

| Drive | Electric motor |

| Material of pump | SS316 |

| Pressure | 0-1.2 mpa |

| Flow | 20 m³/h |

| Power | 5.5 KW |

| Work efficiency | Up to 85% |

| Rate of flow | 0.392 l/rev |

| Self - priming | Up to 9.5m vertical / 30m horizontal |

| Medium | High-corrosive / high-viscous |

| Custom printing | Acceptable |

Construction

1. The quick-release cover

Access to all wetted parts by simply loosening four ring nuts – maintenance without removal of pipe or drive systems.

2. The rotors

Large selection of high-quality rotors for almost pulsation-free pumping of the medium.

3. The casing protection

Depending on its size, the pump is available with and completely without protection plates and liners. When pumping abrasive media containing solids, the protection plates and liners protect the pump casing from wear and can be replaced in a matter of minutes.

4. The intermediate chamber and shaft seal

The large-volume quench chamber is oil-filled and ensures the highest degree of safety. The ideal mechanical seal is selected depending on the medium.

5. The carrier and timing gear

The high-quality and maintenance free carrier and timing gear guarantees a smooth and even operation of the rotors. The result is a long service life of the pump.

Advantages

1. Gap is kept between the rotors and rotors & pump body, no friction, long using-life.

2. Simple assembling and disassembling, easy to maintenance and clean, less easily-damaged parts.

3. High efficiency and energy-saving, low failure, reliable sealing and low noise.

4. In the same type pump, different type rotor can be interchanged.

5. Capable to pump the viscous medium from 1cp to 2million cps.

6. Capable of pumping mixture of gas, fluid and solid medium.

7. Equipped with inverter, the flow can be adjusted as requirement of end-user.

8. Flange, screw or clamp connection can be selected as required.

9. Higher hygienic grade, support CIP, SIP. The surface roughness is 0.2--0.8um, got 3A, FDA certification.

10. Hygienic safety valve is built-in structure.

11. A control unit combined with a frequency inverter regulates the speed of the pump so the liquid sugar is conveyed in doses from a storage tank into the mixing container.

12.The pump is able to convey viscous product, is easy to service and is resistant to pressure.

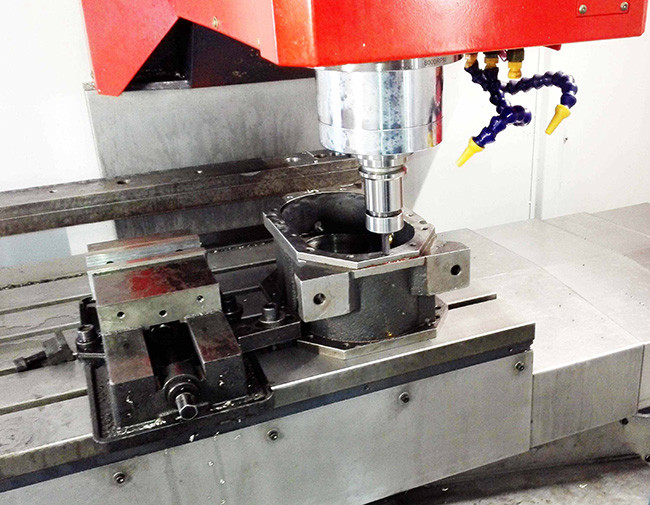

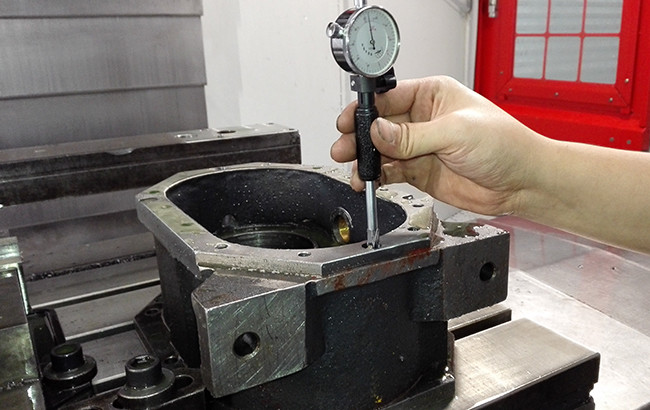

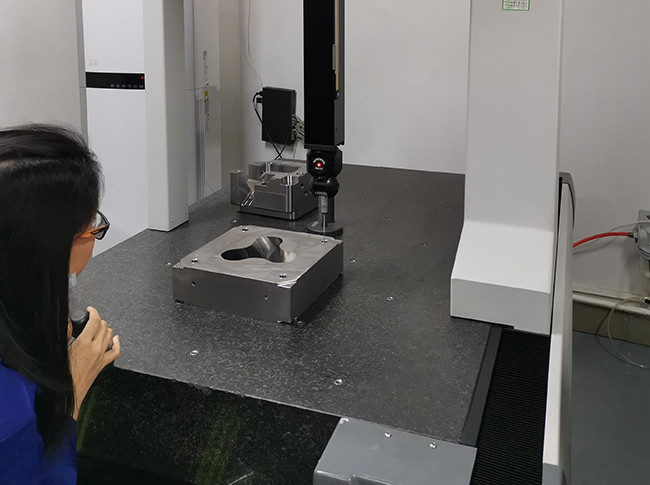

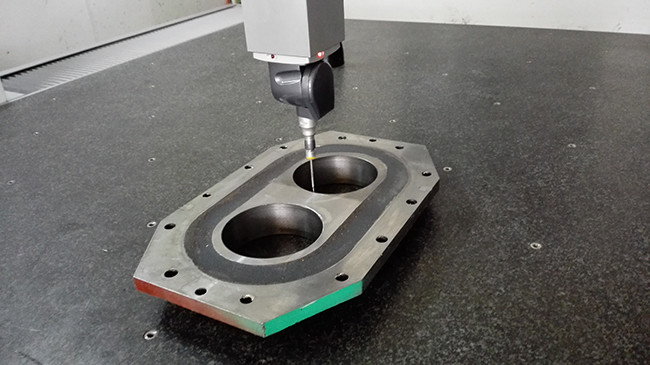

Testing Photo

|

|

Stainless Steel Rotary Pumps For High Viscosity / Corrosive Chemistry Images |